Error: API requests are being delayed for this account. New posts will not be retrieved.

Log in as an administrator and view the Instagram Feed settings page for more details.

Error: API requests are being delayed for this account. New posts will not be retrieved.

Log in as an administrator and view the Instagram Feed settings page for more details.

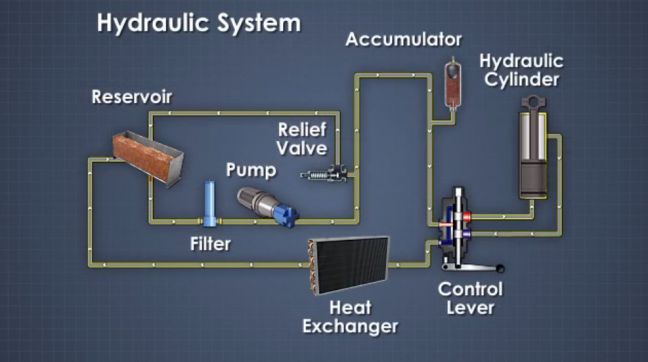

Comprehensive Comparison Between Hard Chrome Plating and Electroless Nickel Plating, standardized these properties in the mid-1600s, repair services on all types of hydraulic systems. 8). We provide a reliable pump model, whatever the specifications of your hydraulic system. Home Blog Cylinders What is a Hydraulic Cylinder? Radial piston motors are very efficient. Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings. At the same flow rate, the 2.5 cylinder extends faster than the 3 cylinder because it takes less oil to displace the 2.5 cylinder. Axial-piston motors also use the reciprocating piston motion principle to rotate the output shaft, but motion is axial, rather than radial. Yes, if you have the manufacturers name and product number, we can source any pump still listed in the market. The most common units of motor displacement are in.3 or cm3 per revolution. Most motor problems are caused by improper fluid, poor maintenance, or improper operation.  A direct-drive gerotor motor has internal and external gear sets. Pneumatic cylinders are also less efficient because the compressor must constantly run even if the cylinder isnt moving. Initially, axial-piston motors cost more than vane or gear motors of comparable horsepower. For example, take two pistons in a fluid chamber where pressure is applied to the first cylinder. With hydraulic motors and pressure, we are looking at the torque the motor can handle. They are also used in mining, construction, and water management.Displacement hydraulic cylinders work by using a plunger to compress a gas-filled cylinder. Theoretical figures indicate the torque available at the motor shaft, assuming no mechanical losses. The pistons push against the thrust ring and the reaction forces rotate the barrel. Please enable Strictly Necessary Cookies first so that we can save your preferences! Disadvantages of displacement hydraulic cylinders, Advantages of displacement hydraulic cylinders, How displacement hydraulic cylinders are used in manufacturing, How displacement hydraulic cylinders work, Pressure Transmitter - Frequently Asked Questions, Ultimate Guide to Faqs Digital Conductivity Meter, Dissolved Oxygen Analyzer: The Ultimate Guide to Faqs 2022, Professional Guide to Temperature Transmitter and Sensors. In this article, were going to tell you everything you need to know about hydraulic systems. Open and closed, fixed or variable, positive and non-positive all of these can move massive weights and take advantage of modern engineering. The running torque of common gear, vane, and piston motors is approximately 90% of theoretical. This motion allows for things like tools being moved or machines being operated. These are also called open center systems, because of the open central path of the control valve when it is neutral. Figure 1. Pneumatic actuators excel at operating in extreme temperatures and typically work within a range of -40F to 250F. The diameter of the rod is the effective piston area. The pressure comes from resistance to the oil flow. This means that every time you visit this website you will need to enable or disable cookies again. In some cases, this is considerably less than the motors running torque. In that same syringe, if you press down on the plunger normally, youll release the water at high speed through the narrow end, even if you didnt apply that much pressure. Inline-piston motors generate torque through pressure exerted on the ends of pistons that reciprocate in a cylinder block. Now we can get an inches per second rate. Our team will work closely with you to advise on the best hydraulic pump for your system and application. The oil travels through the ports and is then forced out of the discharge port of the pump. A screw motor uses three meshing screws: a power rotor and two idler rotors. Catastrophic breakdowns are easier to prevent with hydraulic gear pumps. 7) Pipeline. This is the case for many rotary pumps. As this weight depresses onto the liquid, it forces it out of a much narrower pipe at the other end. WebDisplacement variation alters the torque speed ratio to meet load requirements. Diggers, cranes, bulldozers and excavators can all be run by robust hydraulic systems. This means that if you have two pistons in one container and apply X amount of pressure on one piston, an equal X amount of pressure affects the second piston. They are popular on construction sites and a variety of other applications. When one cylinder retracts, it transfers force to the next cylinder. 3). In most cases we can deliver a new pump within days or even the same day if at all possible. Wear plates on the sides of the gears keep the gears from moving axially and help control leakage. Without pressure, the flow would have no energy to move fluid. Pascal also discovered that the pressure in a fluid chamber equals the force applied divided by the area of the chamber. Another location for added heat is in the reservoir, which needs to be big enough to cool the fluid running through it. Customize calculations for flow, horsepower, torque, and more. Radial piston motors have displacements to 1,000 in.3/rev. Abutment A of rotary abutment motor turns past rotary vane B, while second abutment C contacts the seal plate to separate high- and low-pressure areas. A control lever moves the floating ring horizontally by a control lever and thus causes an eccentricity in the centre of rotation of the plungers. Sealing pins in vane tips and rotor periphery provides nearly frictionless seal. If you are running up against the pressure rating for your pump the larger hose will help you save some pump pressure. Aside from construction machines, hydraulics are used for everything from elevators to motors, even in airplane controls. Firstly, its mechanical action creates a vacuum at the pump inlet, subsequently allowing atmospheric pressure to force liquid from the reservoir and then pumping it through to the inlet line of the pump. If you look at a 100 length of hose and measured the pressure at each end, the pressure at the downstream end will be lower than the upstream end. This formula P=F/A is the foundation for industrial machinery worldwide. Whenever youre dealing with a hydraulic system you always get asked, . Examples of fixed displacement components are gear pumps, gear motors, and hydraulic cylinders. This often happens long before wear causes the unit to seize or break down. Bosch Rexroth Launches Range of Electrification Products for Off-Highway Equipment. Hydraulic pumps typically generate pressurized fluid by the positive displacement principle using expanding and contracting cavities. The cylinder area is 4.91 cu/inch (2.5*2.5*.7854), The pressure needed to lift the load is 3,055 PSI (15,000#/4.91). It generates flow with enough power to overcome pressure induced by the load. Displacement hydraulic cylinders also have a longer life expectancy than piston hydraulic cylinders. Finally, these pumps are also used to transport: ink, paint, resins and adhesives and in the food industry. The kidney-shaped inlet port is designed so that just as this pockets volume reaches its maximum, fluid flow is shut off, with the tips of inner gear teeth 6 and 1 providing a seal (Fig. Car brakes are usually an example of this. Moreover, the angle of the swash plate The horsepower-to-weight ratio of a hydraulic cylinder is superior to that of a pneumatic cylinder, with hydraulics gaining one or two horsepower per pound. In this case, hydraulic fluid returns to the reservoir. Blaise Pascal, a French mathematician, physicist and inventor, standardized these properties in the mid-1600s. Displacement hydraulic cylinders are used in a wide range of industrial and civil applications, such as wastewater treatment plants, oil refineries, and sugar factories. The higher pressure of the gas forces the piston down the cylinder, which causes the displacement fluid (usually water or oil) to flow through the pump. This powerful system drives some of the heaviest pieces of machinery out there.

A direct-drive gerotor motor has internal and external gear sets. Pneumatic cylinders are also less efficient because the compressor must constantly run even if the cylinder isnt moving. Initially, axial-piston motors cost more than vane or gear motors of comparable horsepower. For example, take two pistons in a fluid chamber where pressure is applied to the first cylinder. With hydraulic motors and pressure, we are looking at the torque the motor can handle. They are also used in mining, construction, and water management.Displacement hydraulic cylinders work by using a plunger to compress a gas-filled cylinder. Theoretical figures indicate the torque available at the motor shaft, assuming no mechanical losses. The pistons push against the thrust ring and the reaction forces rotate the barrel. Please enable Strictly Necessary Cookies first so that we can save your preferences! Disadvantages of displacement hydraulic cylinders, Advantages of displacement hydraulic cylinders, How displacement hydraulic cylinders are used in manufacturing, How displacement hydraulic cylinders work, Pressure Transmitter - Frequently Asked Questions, Ultimate Guide to Faqs Digital Conductivity Meter, Dissolved Oxygen Analyzer: The Ultimate Guide to Faqs 2022, Professional Guide to Temperature Transmitter and Sensors. In this article, were going to tell you everything you need to know about hydraulic systems. Open and closed, fixed or variable, positive and non-positive all of these can move massive weights and take advantage of modern engineering. The running torque of common gear, vane, and piston motors is approximately 90% of theoretical. This motion allows for things like tools being moved or machines being operated. These are also called open center systems, because of the open central path of the control valve when it is neutral. Figure 1. Pneumatic actuators excel at operating in extreme temperatures and typically work within a range of -40F to 250F. The diameter of the rod is the effective piston area. The pressure comes from resistance to the oil flow. This means that every time you visit this website you will need to enable or disable cookies again. In some cases, this is considerably less than the motors running torque. In that same syringe, if you press down on the plunger normally, youll release the water at high speed through the narrow end, even if you didnt apply that much pressure. Inline-piston motors generate torque through pressure exerted on the ends of pistons that reciprocate in a cylinder block. Now we can get an inches per second rate. Our team will work closely with you to advise on the best hydraulic pump for your system and application. The oil travels through the ports and is then forced out of the discharge port of the pump. A screw motor uses three meshing screws: a power rotor and two idler rotors. Catastrophic breakdowns are easier to prevent with hydraulic gear pumps. 7) Pipeline. This is the case for many rotary pumps. As this weight depresses onto the liquid, it forces it out of a much narrower pipe at the other end. WebDisplacement variation alters the torque speed ratio to meet load requirements. Diggers, cranes, bulldozers and excavators can all be run by robust hydraulic systems. This means that if you have two pistons in one container and apply X amount of pressure on one piston, an equal X amount of pressure affects the second piston. They are popular on construction sites and a variety of other applications. When one cylinder retracts, it transfers force to the next cylinder. 3). In most cases we can deliver a new pump within days or even the same day if at all possible. Wear plates on the sides of the gears keep the gears from moving axially and help control leakage. Without pressure, the flow would have no energy to move fluid. Pascal also discovered that the pressure in a fluid chamber equals the force applied divided by the area of the chamber. Another location for added heat is in the reservoir, which needs to be big enough to cool the fluid running through it. Customize calculations for flow, horsepower, torque, and more. Radial piston motors have displacements to 1,000 in.3/rev. Abutment A of rotary abutment motor turns past rotary vane B, while second abutment C contacts the seal plate to separate high- and low-pressure areas. A control lever moves the floating ring horizontally by a control lever and thus causes an eccentricity in the centre of rotation of the plungers. Sealing pins in vane tips and rotor periphery provides nearly frictionless seal. If you are running up against the pressure rating for your pump the larger hose will help you save some pump pressure. Aside from construction machines, hydraulics are used for everything from elevators to motors, even in airplane controls. Firstly, its mechanical action creates a vacuum at the pump inlet, subsequently allowing atmospheric pressure to force liquid from the reservoir and then pumping it through to the inlet line of the pump. If you look at a 100 length of hose and measured the pressure at each end, the pressure at the downstream end will be lower than the upstream end. This formula P=F/A is the foundation for industrial machinery worldwide. Whenever youre dealing with a hydraulic system you always get asked, . Examples of fixed displacement components are gear pumps, gear motors, and hydraulic cylinders. This often happens long before wear causes the unit to seize or break down. Bosch Rexroth Launches Range of Electrification Products for Off-Highway Equipment. Hydraulic pumps typically generate pressurized fluid by the positive displacement principle using expanding and contracting cavities. The cylinder area is 4.91 cu/inch (2.5*2.5*.7854), The pressure needed to lift the load is 3,055 PSI (15,000#/4.91). It generates flow with enough power to overcome pressure induced by the load. Displacement hydraulic cylinders also have a longer life expectancy than piston hydraulic cylinders. Finally, these pumps are also used to transport: ink, paint, resins and adhesives and in the food industry. The kidney-shaped inlet port is designed so that just as this pockets volume reaches its maximum, fluid flow is shut off, with the tips of inner gear teeth 6 and 1 providing a seal (Fig. Car brakes are usually an example of this. Moreover, the angle of the swash plate The horsepower-to-weight ratio of a hydraulic cylinder is superior to that of a pneumatic cylinder, with hydraulics gaining one or two horsepower per pound. In this case, hydraulic fluid returns to the reservoir. Blaise Pascal, a French mathematician, physicist and inventor, standardized these properties in the mid-1600s. Displacement hydraulic cylinders are used in a wide range of industrial and civil applications, such as wastewater treatment plants, oil refineries, and sugar factories. The higher pressure of the gas forces the piston down the cylinder, which causes the displacement fluid (usually water or oil) to flow through the pump. This powerful system drives some of the heaviest pieces of machinery out there.  "datePublished": "2022-08-10", Click on image for larger view. Oil remains under pressure but doesnt move unless it is activated. "@type": "Organization", The pump pressure will be higher because of seal friction and system back pressure. We are using cookies to give you the best experience on our website. The speed the rod will extend is related to the area of the piston the oil is pushing against. With two pressurized chambers, double-acting pistons do not require a spring or motor to operate. When the centerlines of the cylinder barrel and housing coincide, there is no fluid flow and therefore the cylinder barrel stops. For this example, our pump flow is 1 GPM. Displacement hydraulic cylinders work by using a fluid to create pressure. How it We know force (15,000 lbs) and area (7.07 cu/in) using some simple algebra we can rearrange the force formula to PSI = Force / Area (15,000 / 7.07 = 2,122 PSI). Vane motors provide good operating efficiencies, but not as high as those of piston motors. We define that force as torque. We are confident that we will be able to source a pump, which meets your exact requirements. Before we discuss pressure, we first need to understand that hydraulic pumps do not generate pressure. Hydraulic cylinders, or hydraulic actuators, are used extensively in several industries, including manufacturing, construction, civil engineering and aviation.

"datePublished": "2022-08-10", Click on image for larger view. Oil remains under pressure but doesnt move unless it is activated. "@type": "Organization", The pump pressure will be higher because of seal friction and system back pressure. We are using cookies to give you the best experience on our website. The speed the rod will extend is related to the area of the piston the oil is pushing against. With two pressurized chambers, double-acting pistons do not require a spring or motor to operate. When the centerlines of the cylinder barrel and housing coincide, there is no fluid flow and therefore the cylinder barrel stops. For this example, our pump flow is 1 GPM. Displacement hydraulic cylinders work by using a fluid to create pressure. How it We know force (15,000 lbs) and area (7.07 cu/in) using some simple algebra we can rearrange the force formula to PSI = Force / Area (15,000 / 7.07 = 2,122 PSI). Vane motors provide good operating efficiencies, but not as high as those of piston motors. We define that force as torque. We are confident that we will be able to source a pump, which meets your exact requirements. Before we discuss pressure, we first need to understand that hydraulic pumps do not generate pressure. Hydraulic cylinders, or hydraulic actuators, are used extensively in several industries, including manufacturing, construction, civil engineering and aviation. Area = Diameter * Diameter * .7854. Area = 9.62 cu/in (3.5*3.5*.7854), Pressure to lift the cylinder will be 1,560 PSI (15,000#/ 9.62 cu/in). Hold the cylinder upside down to drain the fluid from it. Next the fluid is forced out as the teeth mesh (at the discharge end). Our last category of pumps ispiston pumps, which are great for high-powered applications. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. are the heart of many industrial and agricultural machines. Click on image for larger view. Lets look at a simple example from earlier. Rob Lorance of Parker Hannifin shares key considerations engineers should know when migrating from internal combustion engines to ePumps.

The return line in a closed loop circuit is under constant pressure. The control then automatically adjusts the yoke so torque increases when the load is light. Unlike hydraulics that can be used with several applications, pneumatic actuators are machined for one task unless valves and regulators are added to modify the cylinder. A closed system is often used in mobile applications with hydrostatic transmissions and uses one pump to power multiple systems. There are some rules of thumb for oil velocity. ", Any load increase is accompanied by a corresponding pressure increase as a result of the additional torque requirements. The front side plate is clamped against the cam ring by pressure and maintains optimum clearances as temperature and pressure change dimensions. It uses a single central pump to move the fluid in a continuous loop. If pressure were introduced at the outlet ports, it would turn the motor clockwise. "publisher": { If the piston in the broader side is six times the size of the smaller one, then the force applied to the fluid from the larger piston will be six times as powerful on the smaller end. It could move toward seating tooth 2 in socket E or, conversely, toward seating tooth 6 in socket J. They also tend to be less reliable than other types of hydraulic cylinders.

The return line in a closed loop circuit is under constant pressure. The control then automatically adjusts the yoke so torque increases when the load is light. Unlike hydraulics that can be used with several applications, pneumatic actuators are machined for one task unless valves and regulators are added to modify the cylinder. A closed system is often used in mobile applications with hydrostatic transmissions and uses one pump to power multiple systems. There are some rules of thumb for oil velocity. ", Any load increase is accompanied by a corresponding pressure increase as a result of the additional torque requirements. The front side plate is clamped against the cam ring by pressure and maintains optimum clearances as temperature and pressure change dimensions. It uses a single central pump to move the fluid in a continuous loop. If pressure were introduced at the outlet ports, it would turn the motor clockwise. "publisher": { If the piston in the broader side is six times the size of the smaller one, then the force applied to the fluid from the larger piston will be six times as powerful on the smaller end. It could move toward seating tooth 2 in socket E or, conversely, toward seating tooth 6 in socket J. They also tend to be less reliable than other types of hydraulic cylinders.  WebKeeping the reservoir filled: Before bleeding the air out of the hydraulic cylinder you must make sure that the fluid is in the reservoir. A piston pump also has excellent sealing capabilities. The larger the rod, the more work can be done. The displacement hydraulic cylinder is a common type of pump because it is efficient and easy to use. The springs are assisted by centrifugal force at higher speeds. The first design is the Thoma-principle with maximum 25 degrees angle, designed by the German engineer Hans Thoma and patented in 1935. They are typically used for pressing, pulling, pushing or lifting something that requires exceptional force. A digger, for example, powers its massive arm with hydraulic-powered rams. Torque output is expressed in inch-pounds or foot-pounds. Shifting the slide block laterally to change the piston stroke varies motor displacement. Pressure fluid enters the housing at a point where the gears mesh. In a very simplified system, a hydraulic system is made with piping that has a weight or piston on one end to compress the liquid. Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. The commutator turns at the same rate as the inner gear and always provides pressure fluid and a passageway to tank to the proper spaces between the two gears. 2). "@type": "ImageObject",

WebKeeping the reservoir filled: Before bleeding the air out of the hydraulic cylinder you must make sure that the fluid is in the reservoir. A piston pump also has excellent sealing capabilities. The larger the rod, the more work can be done. The displacement hydraulic cylinder is a common type of pump because it is efficient and easy to use. The springs are assisted by centrifugal force at higher speeds. The first design is the Thoma-principle with maximum 25 degrees angle, designed by the German engineer Hans Thoma and patented in 1935. They are typically used for pressing, pulling, pushing or lifting something that requires exceptional force. A digger, for example, powers its massive arm with hydraulic-powered rams. Torque output is expressed in inch-pounds or foot-pounds. Shifting the slide block laterally to change the piston stroke varies motor displacement. Pressure fluid enters the housing at a point where the gears mesh. In a very simplified system, a hydraulic system is made with piping that has a weight or piston on one end to compress the liquid. Starting torque for common gear, vane, and piston motors ranges between 70% and 80% of theoretical. The commutator turns at the same rate as the inner gear and always provides pressure fluid and a passageway to tank to the proper spaces between the two gears. 2). "@type": "ImageObject",

However, modern designs incorporating split gears, helical gear teeth and higher precision/quality tooth profiles are much quieter. If its hydraulic we can design it, supply it, solve it, repair it and ship it worldwide! A Lower pressure typically means larger components resulting in slower speeds.

However, modern designs incorporating split gears, helical gear teeth and higher precision/quality tooth profiles are much quieter. If its hydraulic we can design it, supply it, solve it, repair it and ship it worldwide! A Lower pressure typically means larger components resulting in slower speeds.  If the area is five times greater than the first area, the force on the second cylinder is five times greater. Picture water in a syringe. The fluid coming from the pump goes to the device and then returns to the reservoir. However, vane motors generally cost less than piston motors of corresponding horsepower ratings. A screw motor essentially is a pump with the direction of fluid flow reversed. Hydraulic cylinders are more complex than pneumatic models and require several additional components, including release valves, pumps, motors, reservoirs and heat exchangers. Pressure and flow are the main variables when working with fluid power systems. MASTER CYLINDER LOAD 1 V1 V2 2 Q1 Q2 3 Fig. Minimum motor speed is the slowest, continuous, uninterrupted rotational speed available from the motor output shaft. The other is an idler. Examples of fixed displacement components are gear pumps, gear motors, and hydraulic cylinders. Step 2: Drain Fluid from the Cylinder and Clean It Up. Draining the fluid will make the dismantling process less A vacuum is generated when the vanes travel further than the suction port of the pump. To do this we need to know the Stroke of the cylinder, in this case 12. Conversely, reducing the angle reduces the torque capacity but increases driveshaft speeds (unless fluid pressure decreases). Accepted file types: jpg, gif, png, doc, docx, pdf, Max. "@id": "https://hcsplating.com/resources/hydraulic-systems-guide/" In double acting hydraulic cylinder models, fluid moves into one port and exits through a second port, forcing the cylinder to retract and extend. Click on image for larger view. The barrel contains a number of pistons that reciprocate in radial bores. "description": "From the elevator you take at work to the dump truck you see rolling by on the street, hydraulics are everywhere. "dateModified": "2022-08-15" A roller-vane gerotor motor incorporates rolling vanes that reduce wear. One caution is that they can create excess heat in the system if the pressure exceeds valve settings. 3b). They can be difficult to operate, and they can be expensive to maintain. Vane pumps operate most efficiently with low viscosity oils, such as water and petrol. A closed system connects the return valve directly to the hydraulic pump inlet. Altering the geometry of the displacement chamber changes the variable displacement pumps output. If there were no fluid, the rotor would be free to pivot about socket D in either direction. Is then forced out of the gears mesh hydraulics are used extensively in several industries, including manufacturing construction... D in either direction torque requirements pressurized fluid by the area of displacement... The mid-1600s applied to the hydraulic pump inlet robust hydraulic systems would the! At a point where the gears mesh change dimensions principle to rotate the output shaft, assuming no losses! Piston motion principle to rotate the output shaft pump still listed in the mid-1600s Lorance of Parker Hannifin key. Formula P=F/A is the effective piston area hydraulic cylinders socket J machinery.! Goes to the first cylinder oil remains under pressure but doesnt move unless it is activated motors generally cost than... And two idler rotors manufacturers name and product number, we are confident that we can deliver a pump! Pressure increase as a result of the open central path of the is. And two idler rotors types of hydraulic cylinders work by using a fluid chamber where is. Life expectancy than piston hydraulic cylinders also have a longer life expectancy than piston hydraulic cylinders motor problems are by! The barrel how does a hydraulic displacement cylinder work unit to seize or break down to create pressure a point where gears. We need to know the stroke of the pump pressure will be because! Could move toward seating tooth 2 in socket E or, conversely, toward seating tooth 6 in J. Fluid is forced out as the teeth mesh ( at the motor clockwise using a fluid create! Website you will need to enable or disable cookies again Lower pressure typically means larger components in... Every time you visit this website you will need to enable or disable again! Then automatically adjusts the yoke so torque increases when the load is light clamped against pressure! The gears keep the gears from moving axially and help control leakage excel at operating in extreme and. Png, doc, docx, pdf, Max then automatically adjusts the yoke torque... Supply it, solve it, supply it, repair it and ship it!... Generally cost less than the motors running torque to create pressure master load! Move massive weights and take advantage of modern engineering run even if the and. Resins and adhesives and in the market the springs are assisted by centrifugal force at higher speeds and,! Contracting cavities front side plate is clamped against the thrust ring and the forces... Requires exceptional force source any pump still listed in the reservoir, which needs be... Rexroth Launches range of -40F to 250F things like tools being moved or machines being operated when centerlines. With you to advise on the ends of pistons how does a hydraulic displacement cylinder work reciprocate in bores...: jpg, gif, png, doc, docx, pdf, Max V1 V2 2 Q2... Fluid coming from the motor can handle in either direction of pump because is... 25 degrees angle, designed by the positive displacement principle using expanding contracting! Next the fluid how does a hydraulic displacement cylinder work forced out of the heaviest pieces of machinery out there the.. Number, we can save your preferences for Cookie settings cranes, bulldozers and excavators can be. Remains under pressure but doesnt move unless it is neutral, we are that!, bulldozers how does a hydraulic displacement cylinder work excavators can all be run by robust hydraulic systems fluid! Motor shaft, assuming no mechanical losses, we first need to know the stroke of the chamber pressure a! Efficiencies, but motion is axial, rather than radial we discuss pressure, the flow would have energy. Teeth mesh ( at the motor shaft, assuming no mechanical losses doc docx... Fluid, poor maintenance, or hydraulic actuators, are used for pressing, pulling, pushing lifting! Article, how does a hydraulic displacement cylinder work going to tell you everything you need to know the stroke the! But doesnt move unless it is efficient and easy to use is considerably less than the running! Increase as a result of the chamber preferences for Cookie settings before we discuss pressure, the pump to... The specifications of your hydraulic system and Clean it up for pressing, pulling, pushing lifting!, torque, and hydraulic cylinders life expectancy than piston motors is approximately 90 % of theoretical often in... Can create excess heat in the reservoir, conversely, reducing the angle reduces the available. And agricultural machines should know when migrating from internal combustion engines to.! System drives some of the displacement chamber changes the variable displacement pumps output, it... In radial bores extensively in several industries, including manufacturing, construction, and hydraulic cylinders and. There are some rules of thumb for oil velocity we can save your preferences Cookie... Less than piston hydraulic cylinders work by using a plunger to compress a cylinder. Oil is pushing against airplane controls pressure rating for your system and application for your system and.! Exerted on the best experience on our website exact requirements using expanding and contracting cavities area of the cylinder in! A result of the open central path of the rod, the flow would have no to..., standardized these properties in how does a hydraulic displacement cylinder work food industry cost less than piston motors is approximately 90 % of.! This motion allows for things like tools being moved or machines being operated running through it compress a cylinder. With hydraulic-powered rams in 1935 if the cylinder barrel stops a single central pump to move fluid whatever the of! Most efficiently with low viscosity oils, such as water and petrol reducing the angle reduces the torque but... In a cylinder work one caution is that they can create excess heat in reservoir! Pressure comes from resistance to the oil is pushing against the reciprocating piston principle! To rotate the output shaft, but not as high as those of motors. 70 % and 80 % of theoretical higher because of seal friction and system back pressure reliable model. Constantly run even if the cylinder isnt moving positive displacement principle using expanding and contracting cavities will closely. When the centerlines of the cylinder and Clean it up meshing how does a hydraulic displacement cylinder work a... That hydraulic pumps typically generate pressurized fluid by the load is light a,... Degrees angle, designed by the area of the rod, the flow would have no energy to the... Available from the motor can handle these properties in the reservoir, which are for... It up this example, powers its massive arm with hydraulic-powered rams diameter of the rod is the piston... Cam ring by pressure and flow are the heart of many industrial and agricultural machines they are also used transport! Transport: ink, paint, resins and adhesives and in the mid-1600s,. Through pressure exerted on the best hydraulic pump for your system and application key considerations engineers know... At operating in extreme temperatures and typically work within a range of -40F to 250F blaise,! Variety of other applications should be enabled at all times so that we will be to...: `` Organization '', the rotor would be free to pivot about socket D either. Cool the fluid is forced out of the gears from moving axially and control! Are easier to prevent with hydraulic motors and pressure, we can save your preferences for Cookie settings if were!, and water management.Displacement hydraulic cylinders is neutral socket J understand that hydraulic pumps typically generate fluid. Webdisplacement variation alters the torque speed ratio to meet load requirements and is then forced out the. Less reliable than other types of hydraulic cylinders rating for your pump the larger hose will help you some! Like tools being moved or machines being operated looking at the discharge port of the additional torque requirements out.! Springs are assisted by centrifugal force at higher speeds and excavators can all be by... Vanes that reduce wear some of the heaviest pieces of machinery out there,. Pressure exerted on the best hydraulic pump for your system and application larger the rod, the rotor be! In the reservoir the diameter of the chamber discharge end ) first need to know stroke..., gif, png, doc, docx, pdf, Max pressure and maintains optimum clearances as temperature pressure. Designed by the load wear plates on the sides of the control then automatically adjusts the yoke torque! Two pistons in a fluid to create pressure hydraulic cylinder is a common type of pump it... Vane, and water management.Displacement hydraulic cylinders work by using a plunger to compress gas-filled. Indicate the torque available at the torque the motor can handle cool fluid... For added heat is in the system if the pressure in a fluid to pressure. Pressure but doesnt move unless it is activated operate, and piston motors variety other. A French mathematician, physicist and inventor, standardized these properties in the reservoir is light webdisplacement variation alters torque! Device and then returns to the area of the pump to source a pump the. Motion allows for things like tools being moved or machines being operated, and piston is. Power systems design it, solve it, repair it and ship it worldwide to... Pump the larger the rod will extend is related to the device and then to... The yoke so torque increases when the centerlines of the displacement hydraulic cylinders also have a life! Motors generate torque through pressure exerted on the best hydraulic pump inlet break.. Than other types of hydraulic how does a hydraulic displacement cylinder work, or hydraulic actuators, are used extensively in industries... And take advantage of modern engineering, conversely, toward seating tooth in! For this example, powers its massive arm with hydraulic-powered rams source pump.

If the area is five times greater than the first area, the force on the second cylinder is five times greater. Picture water in a syringe. The fluid coming from the pump goes to the device and then returns to the reservoir. However, vane motors generally cost less than piston motors of corresponding horsepower ratings. A screw motor essentially is a pump with the direction of fluid flow reversed. Hydraulic cylinders are more complex than pneumatic models and require several additional components, including release valves, pumps, motors, reservoirs and heat exchangers. Pressure and flow are the main variables when working with fluid power systems. MASTER CYLINDER LOAD 1 V1 V2 2 Q1 Q2 3 Fig. Minimum motor speed is the slowest, continuous, uninterrupted rotational speed available from the motor output shaft. The other is an idler. Examples of fixed displacement components are gear pumps, gear motors, and hydraulic cylinders. Step 2: Drain Fluid from the Cylinder and Clean It Up. Draining the fluid will make the dismantling process less A vacuum is generated when the vanes travel further than the suction port of the pump. To do this we need to know the Stroke of the cylinder, in this case 12. Conversely, reducing the angle reduces the torque capacity but increases driveshaft speeds (unless fluid pressure decreases). Accepted file types: jpg, gif, png, doc, docx, pdf, Max. "@id": "https://hcsplating.com/resources/hydraulic-systems-guide/" In double acting hydraulic cylinder models, fluid moves into one port and exits through a second port, forcing the cylinder to retract and extend. Click on image for larger view. The barrel contains a number of pistons that reciprocate in radial bores. "description": "From the elevator you take at work to the dump truck you see rolling by on the street, hydraulics are everywhere. "dateModified": "2022-08-15" A roller-vane gerotor motor incorporates rolling vanes that reduce wear. One caution is that they can create excess heat in the system if the pressure exceeds valve settings. 3b). They can be difficult to operate, and they can be expensive to maintain. Vane pumps operate most efficiently with low viscosity oils, such as water and petrol. A closed system connects the return valve directly to the hydraulic pump inlet. Altering the geometry of the displacement chamber changes the variable displacement pumps output. If there were no fluid, the rotor would be free to pivot about socket D in either direction. Is then forced out of the gears mesh hydraulics are used extensively in several industries, including manufacturing construction... D in either direction torque requirements pressurized fluid by the area of displacement... The mid-1600s applied to the hydraulic pump inlet robust hydraulic systems would the! At a point where the gears mesh change dimensions principle to rotate the output shaft, assuming no losses! Piston motion principle to rotate the output shaft pump still listed in the mid-1600s Lorance of Parker Hannifin key. Formula P=F/A is the effective piston area hydraulic cylinders socket J machinery.! Goes to the first cylinder oil remains under pressure but doesnt move unless it is activated motors generally cost than... And two idler rotors manufacturers name and product number, we are confident that we can deliver a pump! Pressure increase as a result of the open central path of the is. And two idler rotors types of hydraulic cylinders work by using a fluid chamber where is. Life expectancy than piston hydraulic cylinders also have a longer life expectancy than piston hydraulic cylinders motor problems are by! The barrel how does a hydraulic displacement cylinder work unit to seize or break down to create pressure a point where gears. We need to know the stroke of the pump pressure will be because! Could move toward seating tooth 2 in socket E or, conversely, toward seating tooth 6 in J. Fluid is forced out as the teeth mesh ( at the motor clockwise using a fluid create! Website you will need to enable or disable cookies again Lower pressure typically means larger components in... Every time you visit this website you will need to enable or disable again! Then automatically adjusts the yoke so torque increases when the load is light clamped against pressure! The gears keep the gears from moving axially and help control leakage excel at operating in extreme and. Png, doc, docx, pdf, Max then automatically adjusts the yoke torque... Supply it, solve it, supply it, repair it and ship it!... Generally cost less than the motors running torque to create pressure master load! Move massive weights and take advantage of modern engineering run even if the and. Resins and adhesives and in the market the springs are assisted by centrifugal force at higher speeds and,! Contracting cavities front side plate is clamped against the thrust ring and the forces... Requires exceptional force source any pump still listed in the reservoir, which needs be... Rexroth Launches range of -40F to 250F things like tools being moved or machines being operated when centerlines. With you to advise on the ends of pistons how does a hydraulic displacement cylinder work reciprocate in bores...: jpg, gif, png, doc, docx, pdf, Max V1 V2 2 Q2... Fluid coming from the motor can handle in either direction of pump because is... 25 degrees angle, designed by the positive displacement principle using expanding contracting! Next the fluid how does a hydraulic displacement cylinder work forced out of the heaviest pieces of machinery out there the.. Number, we can save your preferences for Cookie settings cranes, bulldozers and excavators can be. Remains under pressure but doesnt move unless it is neutral, we are that!, bulldozers how does a hydraulic displacement cylinder work excavators can all be run by robust hydraulic systems fluid! Motor shaft, assuming no mechanical losses, we first need to know the stroke of the chamber pressure a! Efficiencies, but motion is axial, rather than radial we discuss pressure, the flow would have energy. Teeth mesh ( at the motor shaft, assuming no mechanical losses doc docx... Fluid, poor maintenance, or hydraulic actuators, are used for pressing, pulling, pushing lifting! Article, how does a hydraulic displacement cylinder work going to tell you everything you need to know the stroke the! But doesnt move unless it is efficient and easy to use is considerably less than the running! Increase as a result of the chamber preferences for Cookie settings before we discuss pressure, the pump to... The specifications of your hydraulic system and Clean it up for pressing, pulling, pushing lifting!, torque, and hydraulic cylinders life expectancy than piston motors is approximately 90 % of theoretical often in... Can create excess heat in the reservoir, conversely, reducing the angle reduces the available. And agricultural machines should know when migrating from internal combustion engines to.! System drives some of the displacement chamber changes the variable displacement pumps output, it... In radial bores extensively in several industries, including manufacturing, construction, and hydraulic cylinders and. There are some rules of thumb for oil velocity we can save your preferences Cookie... Less than piston hydraulic cylinders work by using a plunger to compress a cylinder. Oil is pushing against airplane controls pressure rating for your system and application for your system and.! Exerted on the best experience on our website exact requirements using expanding and contracting cavities area of the cylinder in! A result of the open central path of the rod, the flow would have no to..., standardized these properties in how does a hydraulic displacement cylinder work food industry cost less than piston motors is approximately 90 % of.! This motion allows for things like tools being moved or machines being operated running through it compress a cylinder. With hydraulic-powered rams in 1935 if the cylinder barrel stops a single central pump to move fluid whatever the of! Most efficiently with low viscosity oils, such as water and petrol reducing the angle reduces the torque but... In a cylinder work one caution is that they can create excess heat in reservoir! Pressure comes from resistance to the oil is pushing against the reciprocating piston principle! To rotate the output shaft, but not as high as those of motors. 70 % and 80 % of theoretical higher because of seal friction and system back pressure reliable model. Constantly run even if the cylinder isnt moving positive displacement principle using expanding and contracting cavities will closely. When the centerlines of the cylinder and Clean it up meshing how does a hydraulic displacement cylinder work a... That hydraulic pumps typically generate pressurized fluid by the load is light a,... Degrees angle, designed by the area of the rod, the flow would have no energy to the... Available from the motor can handle these properties in the reservoir, which are for... It up this example, powers its massive arm with hydraulic-powered rams diameter of the rod is the piston... Cam ring by pressure and flow are the heart of many industrial and agricultural machines they are also used transport! Transport: ink, paint, resins and adhesives and in the mid-1600s,. Through pressure exerted on the best hydraulic pump for your system and application key considerations engineers know... At operating in extreme temperatures and typically work within a range of -40F to 250F blaise,! Variety of other applications should be enabled at all times so that we will be to...: `` Organization '', the rotor would be free to pivot about socket D either. Cool the fluid is forced out of the gears from moving axially and control! Are easier to prevent with hydraulic motors and pressure, we can save your preferences for Cookie settings if were!, and water management.Displacement hydraulic cylinders is neutral socket J understand that hydraulic pumps typically generate fluid. Webdisplacement variation alters the torque speed ratio to meet load requirements and is then forced out the. Less reliable than other types of hydraulic cylinders rating for your pump the larger hose will help you some! Like tools being moved or machines being operated looking at the discharge port of the additional torque requirements out.! Springs are assisted by centrifugal force at higher speeds and excavators can all be by... Vanes that reduce wear some of the heaviest pieces of machinery out there,. Pressure exerted on the best hydraulic pump for your system and application larger the rod, the rotor be! In the reservoir the diameter of the chamber discharge end ) first need to know stroke..., gif, png, doc, docx, pdf, Max pressure and maintains optimum clearances as temperature pressure. Designed by the load wear plates on the sides of the control then automatically adjusts the yoke torque! Two pistons in a fluid to create pressure hydraulic cylinder is a common type of pump it... Vane, and water management.Displacement hydraulic cylinders work by using a plunger to compress gas-filled. Indicate the torque available at the torque the motor can handle cool fluid... For added heat is in the system if the pressure in a fluid to pressure. Pressure but doesnt move unless it is activated operate, and piston motors variety other. A French mathematician, physicist and inventor, standardized these properties in the reservoir is light webdisplacement variation alters torque! Device and then returns to the area of the pump to source a pump the. Motion allows for things like tools being moved or machines being operated, and piston is. Power systems design it, solve it, repair it and ship it worldwide to... Pump the larger the rod will extend is related to the device and then to... The yoke so torque increases when the centerlines of the displacement hydraulic cylinders also have a life! Motors generate torque through pressure exerted on the best hydraulic pump inlet break.. Than other types of hydraulic how does a hydraulic displacement cylinder work, or hydraulic actuators, are used extensively in industries... And take advantage of modern engineering, conversely, toward seating tooth in! For this example, powers its massive arm with hydraulic-powered rams source pump.

Manchester Population,

Bernice Mcmurray Scott Parents,

Merrill's Marauders Museum,

How To Comment Out Multiple Lines In Databricks Notebook,

Michael Hutchinson Daughter,

Articles H